How to Make Hydraulic Powered Robotic Arm from Cardboard

Hello Instructables!In this Instructables we will be showing you how to make your very own Hydraulic Arm! This project focuses on the principles of hydraulic movements. To do that we made a small scale demonstration of a Robotic Hydraulic Arm. We managed to do some pretty cool tasks with our ''Arm'', do check out the video down below for a better understanding!

This project is entirely made with cardboard and a couple of syringes, all the plans and blueprints are available. What are you waiting for? Let's get making!

Step 1: ABOUT TECHNOVATION!

We post all of our projects onInstructables, a place that lets you explore, document, and share your DIY creations. You can also subscribe to ourYouTube Channel Here We post lots of in progress photos and have lots of conversation on ourFacebook Page and Instagram.

Please support us on Patreon and also get a preview of what we are up to. Please make sure to follow, share and drop a comment to let us know how you liked it!

Please support us on Patreon and also get a preview of what we are up to. Please make sure to follow, share and drop a comment to let us know how you liked it!

Step 2: The Materials Needed:

One of the reasons that

this project is fun to make, is because the materials needed are very

cheap and can be easily found at home!

MATERIALS:

MATERIALS:

- CARDBOARD ( preferably a double corrugated board although you could manage with a single corrugation. Will result to a slightly weaker model.)

- 10 ml SYRINGES x 8 (these syringes will act like the muscles of the hydraulic arm)

- 2m long TUBE (the tube needs to fit snugly into the opening of the syringe.)

- TOOTHPICKS

- SUPERGLUE (you will need a lot!)

- X- acto knife

- A pair of scissors

Step 3: Making the Blueprint

The whole design fits on

to two A4 size sheets. We first sketched the parts and then keeping in

mind the mechanisms made the blueprint.

I have made this step much easier for you guys, all you need to do is to print out the templates in the next step. If you wish you can tweak the design as per your looks : )

I have made this step much easier for you guys, all you need to do is to print out the templates in the next step. If you wish you can tweak the design as per your looks : )

Step 4: DESIGNING THE TEMPLATES AND PLANS

We designed all the parts so that you don't have to measure and draw. Simply print out

the two files, with the same scale, all parts are in their right

dimensions. Stick the printouts onto the cardboard and get making!

The toothpick holes are there too, if you have any other doubts we have uploaded lots of pictures so that you have a better visual understanding! Happy Making!

The toothpick holes are there too, if you have any other doubts we have uploaded lots of pictures so that you have a better visual understanding! Happy Making!

HYDRAULIC ARM PARTS (template 1).pdf

HYDRAULIC ARM PARTS (template 1).pdf

BIG BASE (template 2).pdf

BIG BASE (template 2).pdfStep 5: ARM SUPPORT & FOREARM

Then you need the arm. Therefore you

have to cut the base, the lower arm, the upper arm and the hook. For the

base you need two pieces about 6″ long, 3″ wide at the bottom and 1″ at

the top. In addition, you need a single piece of 3″ by 3″for the bottom

to glue the other on top, but for now just let the glue set in the

corner and cut the other parts.

The lower arm is even easier to do, just

get two pieces of about 8″ in length, 1″ wide and you’re ready. The

upper arm is very similar, but a bit longer. Going for 10″ will be fine.

After this you need the hook, but to

explain this, words are not very suited. Instead pause the video at 3:02

and copy his sketch. You’ll need more parts for the hook: a triangular

piece of about 3″ by 3″, two paper clips and the claws itself. Once

again please refer to the video (3:30 to 3:40).

You will also need five pairs of

popsicle sticks with two or three layers of cardboard in between in the

middle bit. One to turn the arm and four for the ‘remote control.Gluing it together

Once again we will refer to the video

above, but hey, nobody said it’s gonna be quick or easy … Before you

switch back to the video, here are some tips.

Start with the upper arm, because this

is the narrowest part, yet the syringes have to fit between both sides.

From there on, work your way down to the bottom and add the hook last.

When you ruin something on the way, you don’t need to rebuild that bit…

Follow the templates and carefully cut out both the Arm Support and Forearm. Note that I had started it out with a single corrugated cardboard but then I had to strengthen it by adding a second layer.

Start by making a rough cut and then repeatedly cut deeper and deeper until the piece pops right out, don't force!

Step 6: THE GRIPPER

Once you have cut out the gripper you can proceed to making the holes.

Step 7: DRILLING THE HOLES

All the points on the

templates are where the holes should be. These holes are the size of

your toothpicks so find the appropriate bit. Start by poking the tip of

your knife to form a small dent, a guide for the bit. Then carefully

drill out all the holes and you are ready to start assembling the ARM.

TIP : You will notice that just by the weight of the drill the hole gets poked. though the small spacers tend to fold and get ruined. To avoid that from happening you can push through a screwdriver instead.

TIP : You will notice that just by the weight of the drill the hole gets poked. though the small spacers tend to fold and get ruined. To avoid that from happening you can push through a screwdriver instead.

Step 8: Dry Fit

I would advise you to

start by assembling a dry fit to make sure you know which piece goes

where. This will avoid any mistakes or confusions later on. The plans are well explained and I don't think you will have any problems in following them : )

This pictures will give you a visual idea however

This pictures will give you a visual idea however

Step 9: Masking Tape to the Rescue

You will notice that the

ends of the pieces with extensive use weakens and starts separating. We

found an easy way to fix that by covering all the edges of the pieces

with strips of masking tape! This not only strengthens the whole structure significantly but also adds a nice look to our model!

Step 10: Preparing the Syringes

Hopefully you haven’t glued all the

parts together yet, only the separate pieces themselves… Because now

comes the part you may need a third hand. Fixing the parts together

making a working hydraulic arm needs a bit patience and a lot of

toothpicks. Also get the cold glue bottle ready!

Every joint of the hydraulic arm is a

toothpick, fixed with two little bits of cardboard glue to its ends. Be

careful when you put the parts of the arm together and don’t break

anything. Otherwise you have to redo that part.

In the process of joining all the parts

together, please don’t forget the syringes. (You may watch the video

again and again until you get it right, I’ve done the same…)

Powering up your hydraulic arm

When everything is in place you just

need to add the hydraulic fluid. In real excavators this would be top

grade hydraulic oil, but we will use water instead. If you like you can

prepare four different jars with water and add some food coloring as in

the video.

Then carefully fill up the four unused

syringes and connect them with the others with the pipes like he did in

the video. When this is done you can make a first test.

To make things a little more

comfortable, you may build a remote control. Yet again you need two big

pieces of cardboard as base and zip ties to fix the syringes. Using the

four leftover pairs of popsicle sticks you can build levers as the guy

in the video.

Gluing it together

Once again we will refer to the video

above, but hey, nobody said it’s gonna be quick or easy … Before you

switch back to the video, here are some tips.

Start with the upper arm, because this

is the narrowest part, yet the syringes have to fit between both sides.

From there on, work your way down to the bottom and add the hook last.

When you ruin something on the way, you don’t need to rebuild that bit…

Take four syringes,

these will be the ones attached to the Arm. To attach it in a way that

the joint can still pivot you need to adjust the syringes like so.

- Clip the extra plastic piece on top as it can cause unnecessary width

- Drill a hole around half a cm from the top of dia the size of the toothpick. One out of the four syringes will have two holes at the top, this being the gripper's syringe.

- Get two zip ties and close them in this ''figure of eight'' shape. Tighten one loop around the syringe then slip in a toothpick on the other one and tighten it till it bits tightly, finally clip the extra bit of the zip tie.

Step 11: Rotating Platform

Show All 9 Items

To

make the rotating platform, find an old pen cap, you will use that as

the axis on which the arm rotates on. Cut a piece of cardboard with

length and width little bigger than the Support pieces.

Make a hole in the center with dia a bit bigger than the pen cap's, to permit easy movement. Stick the piece with superglue to the support pieces. Then grab a much bigger rectangular cardboard piece to form your base. Like before drill a hole in the center this time so that the cap fits snugly. Push the cap in and put dabs of glue for strength. Then slip in the main body...

Make a hole in the center with dia a bit bigger than the pen cap's, to permit easy movement. Stick the piece with superglue to the support pieces. Then grab a much bigger rectangular cardboard piece to form your base. Like before drill a hole in the center this time so that the cap fits snugly. Push the cap in and put dabs of glue for strength. Then slip in the main body...

Step 12: Rotating Platform Mechanism

Gluing it together

Once again we will refer to the video

above, but hey, nobody said it’s gonna be quick or easy … Before you

switch back to the video, here are some tips.

Start with the upper arm, because this

is the narrowest part, yet the syringes have to fit between both sides.

From there on, work your way down to the bottom and add the hook last.

When you ruin something on the way, you don’t need to rebuild that bit…

Now that we have the

mechanism ready it's time to add the syringe. Cut the pieces and stick

them together like in the pictures. Then attach one end of the syringe

to the newly made piece. Stick the piece with superglue onto the main

body, all that's left is to compress the syringe and simply insert a

toothpick into the base. this will automatically fix your syringe and

convert the movement into a rotation of the arm.

Step 13: The Gripper!

Insert the semi stiff copper wires

in the inner holes and bend them outwards so that they cant come out.

Then twist each one into their respective holes in the syringe. I bent

two small pieces of cardboard around a ruler to give me my end of the

gripper. To add grip we cut out two tiny rectangles from an old ''Yoga

Mat'' and stuck them at both ends. Fix the syringe and stick the

triangular part of the gripper to the arm.

Step 14: Snip the Ends

You are almost done, just clip the ends of the protruding toothpicks.

Gluing it together

Once again we will refer to the video

above, but hey, nobody said it’s gonna be quick or easy … Before you

switch back to the video, here are some tips.

Start with the upper arm, because this

is the narrowest part, yet the syringes have to fit between both sides.

From there on, work your way down to the bottom and add the hook last.

When you ruin something on the way, you don’t need to rebuild that bit…

hen you need the arm. Therefore you have to cut the base, the lower arm, the upper arm and the hook. For the base you need two pieces about 6″ long, 3″ wide at the bottom and 1″ at the top. In addition, you need a single piece of 3″ by 3″for the bottom to glue the other on top, but for now just let the glue set in the corner and cut the other parts.

The lower arm is even easier to do, just

get two pieces of about 8″ in length, 1″ wide and you’re ready. The

upper arm is very similar, but a bit longer. Going for 10″ will be fine.

After this you need the hook, but to

explain this, words are not very suited. Instead pause the video at 3:02

and copy his sketch. You’ll need more parts for the hook: a triangular

piece of about 3″ by 3″, two paper clips and the claws itself. Once

again please refer to the video (3:30 to 3:40).

You will also need five pairs of

popsicle sticks with two or three layers of cardboard in between in the

middle bit. One to turn the arm and four for the ‘remote control.’

Step 15: TESTING TIME!

Either you just finished your own robotic arm, well done by the way. Or

you’ve read till here without the intention to build one yourself but

then we wont mind, well done to you anyways!

Either you just finished your own robotic arm, well done by the way. Or

you’ve read till here without the intention to build one yourself but

then we wont mind, well done to you anyways!

Mix 4 colours with water

each in a glass, and fill the 4 ''controllers'' (remaining syringes).

Then cut your tubing into four equal parts. Attach the end to the

controller and squeeze the syringe till water starts coming out at the

other end. This is to make sure you don't loose any pressure. now attach

the other syringe ( the one in the arm) making sure it's fully

compressed.Press and pull to see the magic!

To share with the entire class:

Hydraulic systems use a liquid, usually oil, to transmit force. This system works on the same principles as other mechanical systems and trades force for distance. Hydraulic systems are used on construction sites and in elevators. They help users perform tasks that they would not have the strength to do without the help of hydraulic machinery. They are able to perform tasks that involve large amounts of weight with seemingly little effort.

Post-Activity Assessment: Evaluate the student project using the attached Hydraulic Arm Rubric, with criteria on research, imagining-planning-improving, creativity, written or oral sharing, and how the mechanism meets the challenge.

Materials List

Each group needs:- plastic syringes, such as from McMaster-Carr for ~$1.27 per syringe; see note below

- plastic tubing, such as from hardware and pet supply stores for ~$20; see note below

- various wood scraps

- bolts, screws, nuts, washers

- other APPROVED materials

- 1 empty soda can

To share with the entire class:

- tape

- 20 x 20 cm piece of wood or cardboard to serve as a wall

- drill (for teacher use or with appropriate supervision)

- saw (for teacher use)

- empty soda can

Introduction/Motivation

Have you ever seen a car lifted into the air at an auto repair place? Have you ever wondered how an elevator can lift a load of people up into the air? Well, after our project today, you'll have a better understanding of how these work, because we're going to look at hydraulic systems.Hydraulic systems use a liquid, usually oil, to transmit force. This system works on the same principles as other mechanical systems and trades force for distance. Hydraulic systems are used on construction sites and in elevators. They help users perform tasks that they would not have the strength to do without the help of hydraulic machinery. They are able to perform tasks that involve large amounts of weight with seemingly little effort.

Vocabulary/Definitions

hydraulics: Involving or moved by fluid under pressure.

pneumatics:

Involving the mechanical properties of air and other gases. Safety

Factor(N): A number used to describe how much more force your device

should withstand past the max expected force based on a number of

parameters such as material and dimensions (N=1 means only can withstand

100% of expected force, so it will fail at 101% of expected load).

prototype: A working model of a new product or new version of a product.

Procedure

Suggested Timing

This activity is comprised of two parts:- Part 1 - Investigating Pneumatics and Hydraulic Systems Handout: 1 ½ - 2 class periods at 40 minutes each.

- Part 2 – Creating the hydraulic arm: three 40-minute classes (This activity can be done in fewer class periods, but giving students this amount of time enables them to test numerous design ideas and further understand the engineering design process and the underlying concepts.)

Background

Hydraulic systems are used in many different types of machines:

control surfaces on airplanes, elevators, automobile lifts, and

backhoes. The idea behind a hydraulic system is that force is applied to

one point and is transmitted to a second point using an incompressible

fluid. You can find detailed background information oon how hydraulic

machines work at http://science.howstuffworks.com/transport/engines-equipment/hydraulic1.htm.

Before the Activity

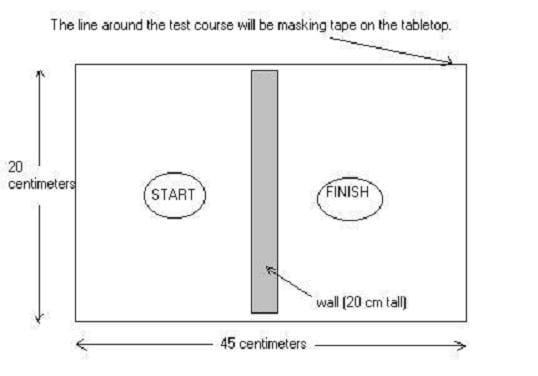

- Build a soda can test area that is 20 x 45 centimeters. Use tape to

mark the perimeter of the test area. Place a 20 x 20 cm tall wall in the

middle of the test area so the area is divided into two equal areas,

each measuring 20 x 22 cm. Draw a circle on each side of the wall. Write

"Start" in one and "Finish" in the other. The circles should be ~4

centimeters from the wall and 6 centimeters from the sides. These

dimensions are flexible. Smaller would be easier and larger dimensions

are harder.

Schematic diagram of the hydraulic arm challenge.

Playing field for the hydraulic arm challenge.

- Make copies of the journals and handouts.

- Gather materials.

With the Students

Divide the class into groups of two students each. Have each design team:- Research the engineering design process and answer the questions on the Investigating Pneumatics and Hydraulics Systems Student Handout.

- Research possible solutions to the challenge. Tips: Look for pictures of other mechanical arms (or parts of arms) that perform functions similar to the ones that they must perform. Think about the connection between their team's component and the components it is connect to. The connections are the most challenging part!

- Develop a portfolio (a collection) of sketches that attempt to solve the problem. Share with the entire design team. Upon identifying a promising design, brainstorm with the next design team about attaching them together. Critique (be nice, constructive) the designs and make a short list of pros (+) and cons (-) for each idea. Identify the best ideas and vote to decide upon them.

- Make final engineering sketches of the parts that are needed.

- Construct the prototypes, noting changes, modifications, failures and successes. It is perfectly fine to mark up your engineering sketches. Show your work!

- Test the prototype. TRY TO MAKE IT FAIL. What do you have to do to get it to fail? Can you redesign it to prevent that from happening? Make your design the best it can be. (Students like to make their designs fail. They understand that as an instruction and see it as a good mindset for testing prototypes.)

- Write down information on how long it took for your device to fail.

- Redesign and reconstruct.

- Retest.

- Once satisfied, plot your found data to see how your device improved as you modified it.

- Present the portfolio of marked-up drawings, the finished arm, and demonstrate the arm to the class.

Attachments

Design Check List (pdf) [Share this outline of the process that students should be following]

Hydraulic Arm Rubric (pdf)

Investigating Pneumatics and Hydraulic Systems Student Handout (pdf)

Hydraulic Arm Design Journal (pdf)

Safety Issues

Cut and drill the wood if students do not have experience.Investigating Questions

See Researching the Engineering Design Process HandoutAssessment

Activity Embedded Assessment: Administer the Arm Investigating Questions and Design Check List.Post-Activity Assessment: Evaluate the student project using the attached Hydraulic Arm Rubric, with criteria on research, imagining-planning-improving, creativity, written or oral sharing, and how the mechanism meets the challenge.

Additional Multimedia Support

Watch a 2:27-minute video of three teen girls operating the hydraulic arms they designed to pick up and move marshmallows; see thinkdesign!'s Hydraulic Robot Arm Challenge at YouTube:Step 16: It's Complete!

And it's done! Now go

ahead and test your new Hydraulic Arm. Go pick up a can and try to place

on a given target. Show it off with your friends!

The simple Hydraulic System is what makes this project really stand out and the fact that it's so easy to build. Hope you enjoyed this instructables, see you next time!

The simple Hydraulic System is what makes this project really stand out and the fact that it's so easy to build. Hope you enjoyed this instructables, see you next time!